Grinder pumps are an essential component in many modern wastewater systems, especially where solids and debris must be processed before being pumped into a sewer or treatment facility. Selecting the correct grinder pump ensures system reliability, reduces maintenance costs, and protects downstream infrastructure. At Wastewater Supply, we provide expert guidance and a wide range of pump solutions to help you make the right choice based on your system’s specific demands.

What is a Grinder Pump?

Contents

A grinder pump is a type of wastewater pump equipped with rotating blades designed to macerate solid waste into a fine slurry. This allows for smoother transportation through smaller-diameter pipes, making it ideal for applications where gravity flow is not possible or where solids could clog conventional sewage pumps.

Grinder pumps are commonly used in:

- Residential and commercial sewer systems

- Low-pressure sewer applications

- Remote or elevated locations where gravity flow is limited

- Industrial and institutional facilities with high-solid-content wastewater

Key Factors to Consider When Selecting a Grinder Pump

1. Application Type

Understanding the environment where the pump will operate is the first step. Residential systems typically require compact, lower-flow models, while commercial and municipal settings demand higher-capacity units with robust grinding capabilities. Be sure to evaluate the system’s volume and expected solids content.

2. Flow Rate and Head Requirements

Every grinder pump has performance specifications in terms of flow rate (GPM) and total dynamic head (TDH). Selecting a pump that meets the system’s lift and distance requirements is crucial. Undersized pumps may result in frequent clogging, while oversized units can lead to unnecessary energy use and higher operational costs.

3. Motor Power and Voltage

Grinder pumps typically range from 1 HP to over 10 HP, depending on the application. It’s important to match motor size with demand to ensure reliability and efficiency. Also consider the available electrical supply—single-phase or three-phase—and ensure compatibility with your control panel and system infrastructure.

4. Solids Handling Capability

The quality of the grinder mechanism directly affects the pump’s ability to process challenging materials. Look for pumps with hardened cutter assemblies, corrosion-resistant components, and proven track records in your type of application. At Wastewater Supply, we offer pumps that are engineered to handle everything from wipes and sanitary products to food waste and sludge.

5. Construction Materials

Grinder pumps are often installed in harsh environments, so materials matter. Cast iron and stainless steel housings offer superior durability and corrosion resistance. If your system handles aggressive or corrosive fluids, select a pump built with chemical-resistant components to ensure long-term performance.

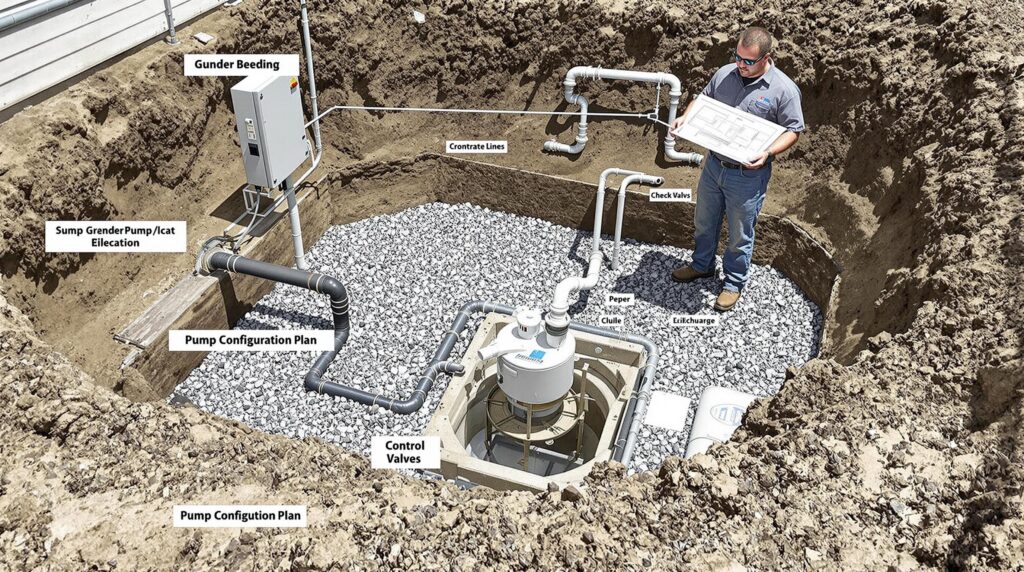

Installation Environment and Configuration

Where and how your grinder pump is installed also influences the best model for your needs. Key considerations include:

- Submersible vs. Dry Pit: Most grinder pumps are submersible, installed directly within a basin or tank. However, dry pit options may be preferred for easier maintenance access in some facilities.

- Control Panel Integration: Ensure the pump is compatible with your control panel’s voltage, phase, and sensor inputs. We provide complete systems including panels, floats, and alarms tailored to your configuration.

- Pump Guide Rail Systems: For ease of service and safe removal, especially in deeper installations, consider pumps with compatible guide rail systems.

Maintenance and Reliability

A well-selected grinder pump should deliver years of service with minimal maintenance. Features to look for include:

- Thermal overload protection

- Seal fail detection

- Oil-filled motors for improved cooling

- Replaceable cutter assemblies

Wastewater Supply offers OEM replacement parts and technical support to ensure your grinder pump remains in peak operating condition throughout its lifecycle.

Our Expert Recommendations

With so many models and options on the market, selecting the right grinder pump can feel overwhelming. At Wastewater Supply, our team has extensive field experience and product knowledge to guide you through the selection process. Whether you’re designing a new system or replacing an aging pump, we offer tailored solutions to meet your exact requirements.

Need Help Choosing the Right Grinder Pump?

Let us help you find the perfect grinder pump for your wastewater system. Contact us today to speak with a pump specialist. We’ll assess your application and recommend a reliable, cost-effective solution that performs under pressure.

About Wastewater Supply: Wastewater Supply is your trusted source for high-quality pumps, OEM parts, and wastewater system solutions. We specialize in grinder pumps, fiberglass basins, control panels, and more—designed to keep your systems operating efficiently and reliably in even the toughest conditions.