As the summer heat fades and fall approaches, it’s crucial to prepare your wastewater equipment for the seasonal transition. Preventative maintenance before fall helps avoid costly repairs, improves system efficiency, and ensures compliance with environmental regulations throughout the colder months. Properly maintained wastewater systems can handle the challenges of temperature changes, increased organic load, and potential weather disruptions.

Why Fall Preparation is Critical for Wastewater Equipment

Contents

- 1 Why Fall Preparation is Critical for Wastewater Equipment

- 2 Top Preventative Maintenance Tips for Wastewater Equipment

- 2.1 1. Thoroughly Inspect Pumps and Motors

- 2.2 2. Clean and Service Screening and Grit Removal Systems

- 2.3 3. Check Aeration and Biological Treatment Systems

- 2.4 4. Inspect and Maintain Pipelines and Valves

- 2.5 5. Review and Adjust Chemical Treatment Plans

- 2.6 6. Remove Sediment and Sludge from Tanks and Clarifiers

- 3 Additional Steps to Prepare for Fall and Winter

- 4 Partnering with Experts for Reliable Wastewater Equipment Maintenance

- 5 Contact Us to Schedule Your Pre-Fall Maintenance

The shift from summer to fall brings cooler temperatures and often increased rainfall, which can impact wastewater treatment processes. Biological activity may slow down, pipes and equipment are susceptible to temperature fluctuations, and stormwater inflows can increase system loads. Taking proactive steps before fall helps maintain operational stability and extends equipment life.

Top Preventative Maintenance Tips for Wastewater Equipment

1. Thoroughly Inspect Pumps and Motors

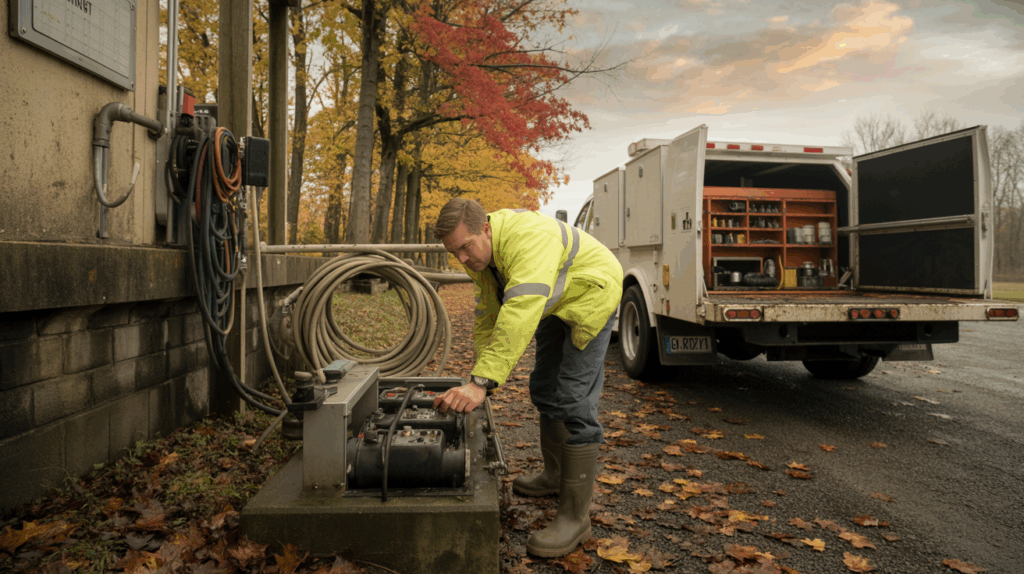

Pumps are the heart of any wastewater system. Before fall, inspect all pumps and motors for signs of wear, corrosion, or damage. Lubricate moving parts and verify electrical connections are secure. Replace any worn seals or bearings to prevent leaks and mechanical failures during colder months.

2. Clean and Service Screening and Grit Removal Systems

Debris and grit accumulate over the summer and can impede flow and damage downstream equipment. Clean screens and grit chambers thoroughly to ensure efficient removal of solids. Regular cleaning prevents blockages and reduces maintenance needs during fall and winter.

3. Check Aeration and Biological Treatment Systems

Lower fall temperatures affect the efficiency of biological treatment processes. Inspect aerators and diffusers to ensure proper oxygen delivery. Clean any buildup on equipment surfaces and calibrate dissolved oxygen sensors to optimize treatment performance.

4. Inspect and Maintain Pipelines and Valves

Temperature fluctuations can cause expansion and contraction of pipes, potentially leading to leaks or breaks. Conduct camera inspections or manual checks for cracks, corrosion, or blockages. Lubricate valves and confirm they operate smoothly to prevent flow disruptions.

5. Review and Adjust Chemical Treatment Plans

Changing wastewater composition in the fall may require adjustments to chemical dosing. Test water quality parameters such as pH, nutrient levels, and total suspended solids. Consult your chemical supplier to modify treatment protocols and maintain compliance with discharge standards.

6. Remove Sediment and Sludge from Tanks and Clarifiers

Sludge accumulation reduces tank capacity and can cause odor problems if left unchecked. Schedule desludging or cleaning of tanks and clarifiers before fall to maintain optimal system operation and prevent downstream complications.

Additional Steps to Prepare for Fall and Winter

- Insulate exposed equipment and pipes: Prevent freezing and damage during cold spells.

- Test backup power systems: Ensure generators and emergency power supplies are operational for storm-related outages.

- Update maintenance logs and emergency response plans: Document recent work and refine procedures for rapid response to unexpected issues.

Partnering with Experts for Reliable Wastewater Equipment Maintenance

Effective preventative maintenance often requires specialized expertise and equipment. Working with a trusted wastewater supply partner ensures you have access to quality parts, reliable service, and technical guidance tailored to your system’s needs.

At Wastewater Supply, we provide comprehensive products and solutions designed to support your wastewater equipment through seasonal changes. From pumps and screening equipment to chemicals and monitoring tools, we help you maintain a robust and compliant system year-round.

Contact Us to Schedule Your Pre-Fall Maintenance

Don’t wait for fall challenges to impact your wastewater operations. Contact us today to discuss your equipment maintenance needs and learn how our products and expertise can help you prepare effectively for the upcoming season. Proactive maintenance is key to long-term system reliability and environmental compliance.